maintenance of jaw crusher

maintenance of jaw crusher

Maintenance and Repair of Jaw Crusher | JXSC Mine.

Learn More

First of all, the ore feed must be stopped, and after the ore in the crushing chamber is all discharged, then stop the crusher and belt conveyor. It should be noted that if the crusher stops suddenly for any reason, the accumulated ore in crushing chamber must be cleared before the crusher is ready to start again. Maintenance and repair

Learn More

Make sure the lubrication of the bearings in the feeder and the jaw crusher is good; make sure there is enough lubrication oil in the reducer box; make sure the

Learn More

Maintenance Tips For Jaw Crusher Machine. Aug 26, Overall, one of the best ways for you to ensure continuous and safe operation of a jaw crusher

Learn More

maintenance of jaw crushers filetype pdf – Crusherb2b.com. maintenance of jaw crushers filetype pdf Crushing and grinding machine supplier in all of the world: liming. ★ used in stone,gold,sand,coal,iron ore

Learn More

Feb 11, · Successful jaw crusher maintenance requires the right resources, the right tools and the right method. When an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible. Here are main steps for jaw crusher maintenace. Firstly, Cleanliness is key.

Learn More

MAINTENANCE OF JAW CRUSHER. 1. In order to guarantee normal operation of machine and prolong service life, inject lubrication oil is needed regularly. 2. About 50% to 70% of volume of all bearing housings should be filled with grease. Change the grease each 3-6 month, clean the roller bearing carefully. 3.

Learn More

Regardless of your chosen supplier, it is vital that any crusher repair (even with severe production demands to get back up and running) should consider

Learn More

ALWAYS follow the procedures outlined in the operating and maintenance instructions. To avoid the risk of electric shock, ALWAYS isolate this equipment from the supply source before removing any guards or covers or performing any maintenance or adjustment to the equipment.

Learn More

Daily Maintenance Of Jaw Crusher Apr 10, 1. Check the heating of the bearing. For rolling bearings, the temperature cannot exceed 70°C, and for sliding bearings, the temperature cannot exceed 60°C. If the temperature exceeds the specified temperature, stop immediately for inspection and troubleshooting. 2.

Learn More

The maintenance work of jaw crusher needs to be carefully carried out during the operation of the equipment and during the shutdown inspection. After the equipment has problems, it should be dealt with in time, so as to ensure the long-term use of the equipment. Jaw crusher is a relatively popular mine crushing equipment, which has the

Learn More

Versan Engineering - Offering One Time Jaw Crusher Maintenance Service, For Stone, Commercial in Sangareddi, Telangana. Read about company.

Learn More

Ensuring that the size of raw material is appropriately matched to the jaw opening, can alleviate blockage incidents. This can be achieved by

Learn More

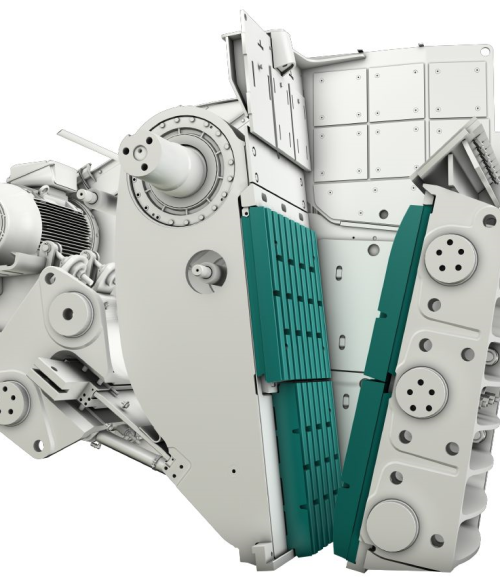

The jaw crusher line is designed for the motor sizes listed in RPG and technical specifications. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

Learn More

The jaw crusher has the characteristics of large crushing ratio, high output, simple structure, uniform crushing particle size and simple operation and maintenance. The working characteristics and

Learn More

We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap

Learn More

Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of the jaw.

Learn More

SEPOR, INC. 718 N FRIES AVE. WILMINGTON, CA 90744. 310 830 6601. Fax: 310 830 9336 [email protected]. OPERATING AND MAINTENANCE MANUAL. MINI JAW CRUSHER

Learn More

Jaw stone crusher are known as jaw crusher and usually operate under harsh working conditions. When using, it is necessary to strictly abide by the operation rules and maintenance system, find and repair the worn parts in time, and eliminate various faults. Maintenance of Jaw Stone Crusher. 2022-07-11 17:32:30. SHARE TO: Jaw stone crusher

Learn More

Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies every day, and make sure bolts are fastened securely. Maintain crusher backing to ensure proper vibration and impact protection. Keep breathers clean. Make sure the toggle area is clean, especially prior to any adjustments.

Learn More

Maintain the daily upkeep · Inspect the jaw ties and cheek plates daily for wear and the bolts for tightness. · Check your closed side setting to

Learn More

The Most Practical Jaw Crusher Repair and Maintenance . 2022-7-20 It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you

Learn More

Mastering jaw crusher maintenance skills is benefit to improve machine life span as well as production. here you will learn how to change

Learn More

Jaw crusher maintenance Jaw Crusher Introduction. The Jaw Crusher Model 241-36 WD is designed for the rapid reduction of rocks into granular particles. jaw crusher problems, maintenance, jaw closed side setting.

Learn More

Perform Daily Visual Inspections · crusher maintenance Don't Abuse Your Machines · Use Correct and Clean Fluids · crusher maintenance

Learn More

The maintenance and inspection of jaw crusher mainly focus on below aspects: (1) Check the temperature of the bearing. The temperature of bearing shall not over 60 ℃ (antifriction bearing temperature shall not over 70℃).

Learn More

some maintenance matters about jaw crusher to all the customers. First, the jaw crusher (jaw) lubrication 1, Before the jaw crusher started, the thrust plate and the thrust plate between the supports should be injected into the right amount of grease. 2, Notice the friction surface lubrication, and ensure the normal operation of the machine and prolong its service life. 3, The jaw crusher

Learn More

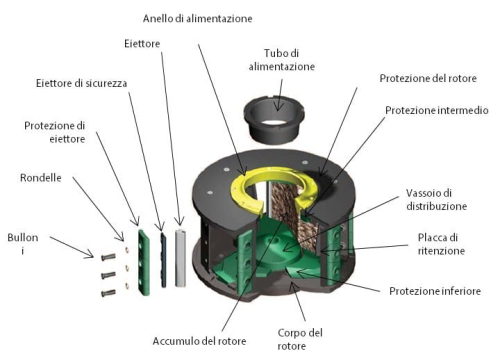

The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etc. Replace badly wearing parts in time. Regularly inspect temperature of the rotor, motor and bearing, etc.

Learn More

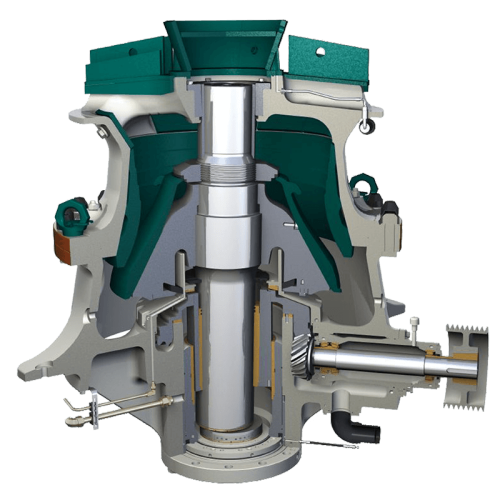

C160™ jaw crusher is engineered for safe operation and easy maintenance. There are limited number of service points, all with easy and safe access. The operation, condition monitoring and greasing can be fully automated. Lifting tools for components are supplied as standard to make maintenance simpler and safer.

Learn More

Jones advises: “Always ensure the wear parts are fastened into the machine properly. With jaw crushers, if you allow the jaw dies to move during

Learn More

Checklist For Daily Crusher Maintenance - Crusher USA daily maintenance check list for stone jaw crusher. daily maintenance check list for stone jaw crusher. shanghai shibang machine co. , ltd. is a hig Chat Now; crusher preventative maintenance checklist scheduled preventive maintenance checklist grinding machine.

Learn More